Three Kinds of Vacuum Drum Filter

Vacuum Drum Filters process slurry and discharge cake in a continuous process and can be applied in sludge dewatering, waste water treatment, chemical manufacturing, mineral mining and the food processing industry. It is the best choice for a slurry with variable cake thickness, moisture content, and stickiness.

Working principle

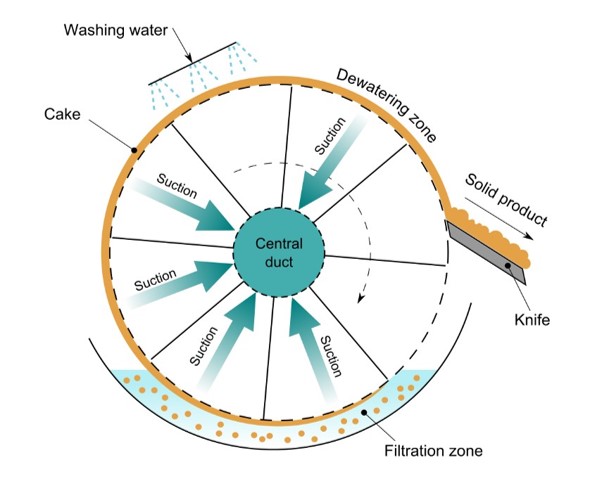

The outer surface of the vacuum drum filter is divided into multiple functional areas:

- Suction and Filtration area: At this time, the drum for vacuum filtering, the surface of the drum gradually formed a filter cake.

- Washing and cleaning area: After the filter cake formed enter into the washing area for the cake washing.

- Dewatering area: After washing the cake into the drying area, the residue of the filter cake will be sucked away.

- Back-blow Zone: At this point, compressed air enters into the back-blow zone, blow off the dried filter cake and scrape off by the scraper. After scraped off the filter cake, into the filter cloth recycling system, and then enters into the sink liquid level for the next cycle.

Different types

1.Scraper Type: suitable for moderate solid concentration and specific gravity, low viscosity and no gum.

2. Folding Belt Type: suitable for dewatering fine and sticky material.

3. Precoated Type: For the filtration of the suspension with low concentration, fine particles, colloid, easy to block the filter cloth, and the filtrate with extremely high filtrate clarity is required.

Application

Applied in sugar, starch, gypsum and any other powdered particles filtration and dryness. Food, fermentation, medicine, chemical industry, sewage treatment, oil and other industries.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160